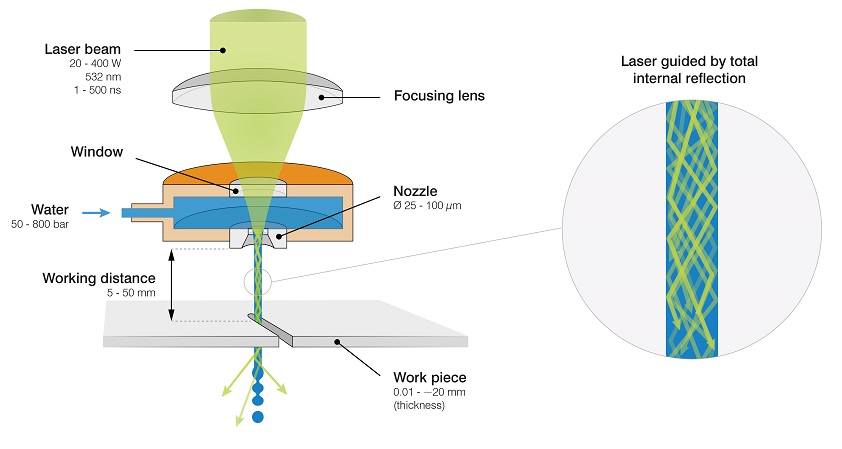

The Laser MicroJet® Technology

A Simple Principle

The Laser MicroJet (LMJ) is a hybrid method of machining, which combines a laser with a "hair-thin" water jet that precisely guides the laser beam by means of total internal reflection in a manner similar to conventional optical fibers. The water jet continually cools the cutting zone and efficiently removes debris.

As a “cold, clean and controlled laser”, Synova's LMJ technology resolves the significant problems associated with dry lasers such as thermal damage, contamination, deformation, debris deposition, oxidation, micro-cracks and taper.

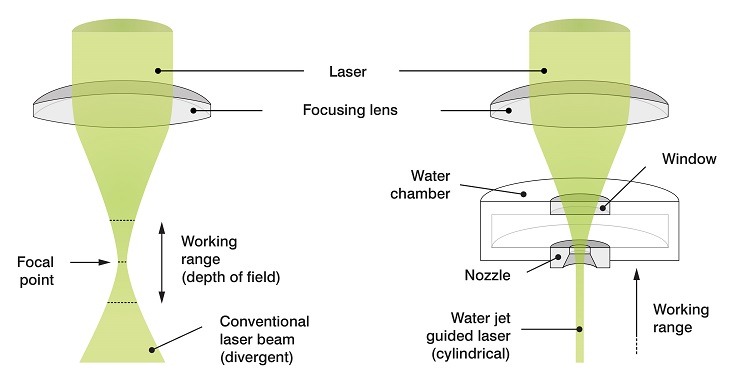

Comparison of Conventional and MicroJet Laser Beams

(Left)

The conventional focused laser beam has a limited working distance of just a few millimetres to even fractions of a millimetre due to beam divergence. This not only makes precise focusing and distance control necessary, it also limits the ratio of kerf width to depth.

(Right)

The LMJ technology employs a laser beam that is completely reflected at the air-water interface. The beam can be guided over a distance of up to 10 cm, enabling parallel high aspect ratio kerfs. No focusing or distance control is required.

Technical Parameters