William M. Steen Award 2022 for "5-Axis Laser MicroJet"

Laser Institute of America, LIA

Synova has made possible what physically seems to be impossible. No focus, no taper, thickness range from microns to centimeters

No HAZ, depositions or burrs. No weakening of the material

Micron precise, smooth edges, sharp corners

24/7 production & integration into fully automated production lines

Low cost of ownership (few consumables, low tool wear)

All Synova laser cutting systems are based on the unique Laser MicroJet technology, performing highly accurate and fast machining without thermal damage, taper and depositions. LMJ production machines have a proven performance of 97% uptime (semiconductor industry).

Our application laboratory is available for sample testing, feasibility studies and application development.

Are you interested in a test?

We offer ‘job shop’ cutting services at our headquarters and international MMCs. Quick and hassle-free, ideal for prototypes and small batches.

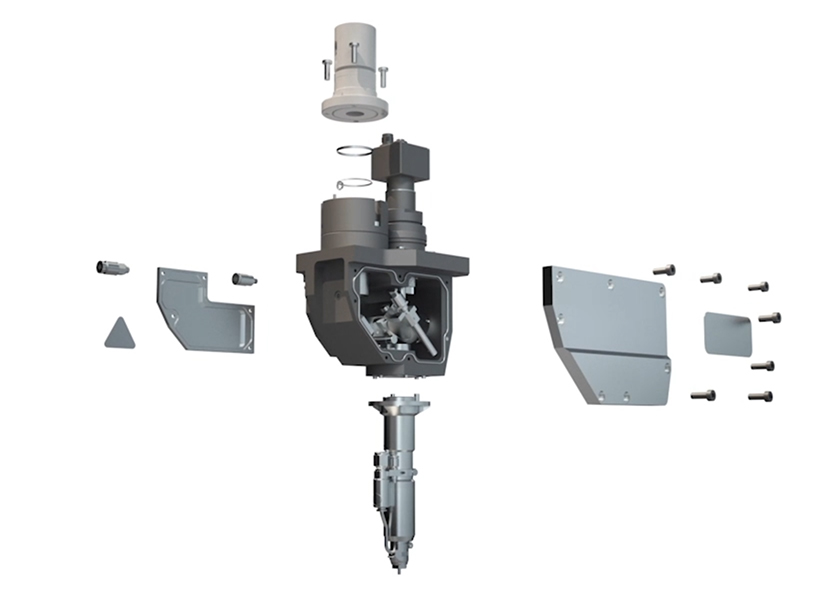

With the LMJ-iP Synova provides customers with the flexibility to integrate core LMJ components into existing production facilities.

The Laser MicroJet technology, including IP portfolio, is now accessible to interested parties through licensing.

Turbine blades, shrouds, vanes and other aero-engine components, satellite sensors

Silicon wafers, integrated circuits, smart cards, sensor chips, MEMS, solar cells

Natural diamonds, lab-grown diamonds (CVD, HPHT)

Tool inserts, superhard materials such as PcBN, PCD, SCD and CVD diamond

Surgical instruments, implants, tubes, flat stents, electronic components

Watch movement components such as toothed wheels, decorative parts

It all began with the invention of the liquid jet guided laser at the Federal Institute of Technology (EPFL) in Lausanne, Switzerland in the 1990s.

Synova is now a company with global reach. Our focus lies on delivering high-quality cutting solutions and services to our customers.

What makes us unique?

Years of experience in laser-machining

Years of commercialization

Employees, among them 30 R&D engineers

Global LMJ competence centers

National and international awards

Application tests

LMJ machines installed worldwide

Million USD invested in R&D

Patents

William M. Steen Award 2022 for "5-Axis Laser MicroJet"

Laser Institute of America, LIA

Technology Innovation Award (Europe, Israel, Africa)

Frost & Sullivan

Laser MicroJet: One of “World’s Most Amazing Breakthroughs in Science & Technology”

McGraw-Hill Yearbook of Science & Technology, U.S.A.

Second Best Tool for Wafer Processing

EuroAsia IC Industry

European Award for technology Innovation

Frost & Sullivan

Entrepreneur of the Year 2004 (Finalist)

Ernst & Young

Förderpreis Technopark Zürich

Technopark Zürich

Technologiestandort Schweiz

OSEC, Swiss Center for Trade Promotion

Sonderpreis Espace Mittelland

Cantons of Central Switzerland

KTI-Label

Swiss Innovation Promotion Agency, Bern

May 31, 2024 - Jun 3, 2024

Las Vegas, NV - USA (The Venetian)

Booth no. 53087

Jun 11, 2024 - Jun 14, 2024

Palexpo-Geneva, Switzerland

Sep 9, 2024 - Sep 14, 2024

McCormick Place, Chicago, USA

We count companies from various industries among our customers. Here is a selection of our valued clients.