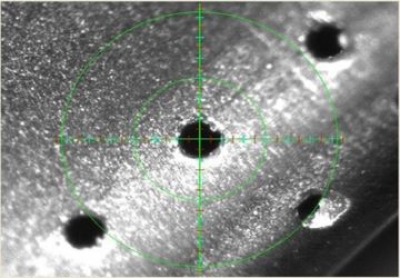

Synova's Laser MicroJet (LMJ) was used to drill Ceramic Matrix Composite (CMC) shrouds. Laser MicroJet's gentle, precise, and high-volume processing for an exigent aero application is of advantage.

Case Studies

How Our Clients Use LMJ Systems

With its customized solutions, Synova helps companies to be one step ahead of the competition.

Take a look at the case studies below to get a detailed insight of customer applications.

- Advanced Composites

- Advanced Materials such as GaN

- Alloys

- Binderless Polycrystalline Diamond (BLPCD)

- Brass

- CVD Crystal

- Carbide Substrate

- Ceramic Matrix Composite (CMC)

- Ceramics

- Coated Superalloy

- Copper

- CuBe

- Gold

- HPHT Crystal

- Indium Gallium Nitride

- Metal

- Metal Alloys

- Metal Deposition

- Natural Diamond

- Ni Superalloy

- Nickel Foils

- Nitinol

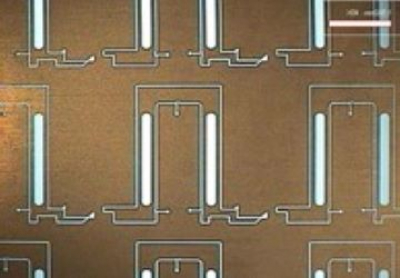

- Photolithography

- Platinum

- Platinum-Iridium

- Polycrystalline Cubic Boron Nitride (CBN)

- Silicon

- Silicon Carbide

- Silicon with gold coating

- Stainless Steel

- Steel

- Tungsten

- Various

Energy and Aviation

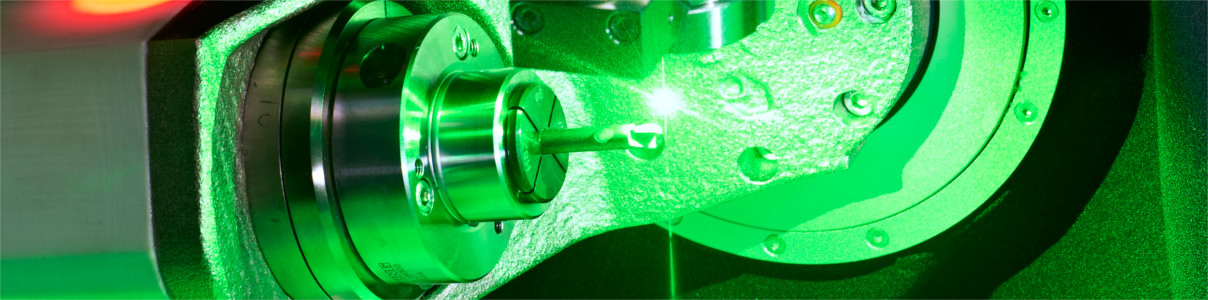

Processing of Aero-Engine Components

LMJ: aero-engine components. Drilling, milling, cutting up to a few mm thickness.

Application Areas

Energy and AviationMaterial

Ceramic Matrix Composite (CMC)Ni Superalloy

Process

DrillingMilling

Cutting

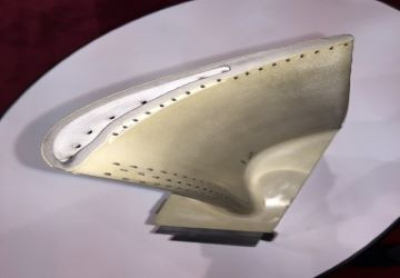

Drilling of Turbine Blades

Synova's Laser MicroJet (LMJ) was used to drill cooling holes in turbine blades in coated superalloy. Chipping or micro cracking of the coating can be avoided thanks to this gentle process.

Application Areas

Energy and AviationMaterial

Coated SuperalloyProcess

Drilling

High-Speed Drilling of Shaped Holes

High-speed drilling of shaped holes in blades and vanes with LMJ for industrial gas turbines, no thermal stress and minimal recast.

Application Areas

Energy and AviationMaterial

AlloysProcess

DrillingShaping

Drilling of Gas Turbine Blades

Drilling of industrial gas turnine blades by avoiding heat related problems and maintaining high productivity by the use of LMJ.

Application Areas

Energy and AviationMaterial

AlloysProcess

DrillingShaping

Tool Manufacturing

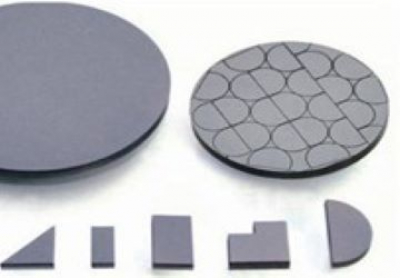

Cutting of CBN Blanks without Heat Damage

When cutting CBN (Cubic Boron Nitride) blanks with LMJ the result exceeds the quality of dry laser cutting as heat damages and rough edges are avoided.

Application Areas

Tool ManufacturingMaterial

Polycrystalline Cubic Boron Nitride (CBN)Process

Cutting

Cutting of Binderless Polycrystalline Diamond

Fabricating top quality discs made of Binderless Polycrystalline Diamond with LMJ is less time- and tool-consuming than with conventional methods such as grinding.

Application Areas

Tool ManufacturingMaterial

Binderless Polycrystalline Diamond (BLPCD)Process

Cutting

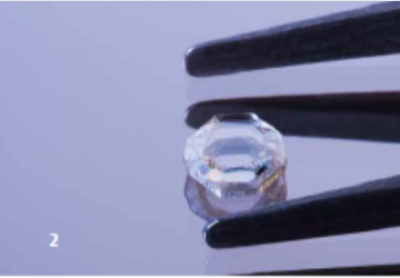

Pre-Cutting of Tool Inserts

When using LMJ to cut diamond tool inserts 99% of the diamond material can be removed at high speed before a final polishing step.

Application Areas

Tool ManufacturingMaterial

HPHT CrystalProcess

Pre-Cutting

Cutting PCD and CBN Tools

Cutting PCD, CBN tools: no micro cracks, HAZ, oxidation possible with LMJ. Verticality, narrow tolerances, low roughness, and sharp edges.

Application Areas

Tool ManufacturingMaterial

TungstenCarbide Substrate

Process

Finishing

Super Hard Tool Making

Synova's Laser MicroJet's (LMJ) higher quality 3D machining of inserts and complex multi-tip tools enables new applications with better operating cost.

Application Areas

Tool ManufacturingMaterial

TungstenProcess

CuttingDiamonds and Jewelry

Cutting of Large Diamonds

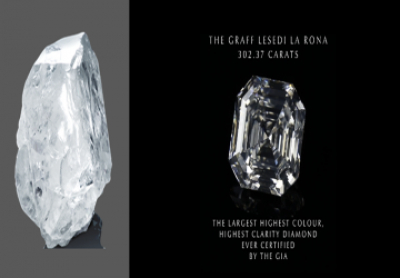

The Graff Lasedi La Rona

The Graff Lasedi La Rona is the largest highest color, highest clarity diamond ever certified by the GIA. Thanks to parallel cutting with LMJ the weight loss is minimal.

Application Areas

Diamonds & JewelryCutting of Large Diamonds

Material

Natural DiamondProcess

Cutting

The Queen of Kalahari

The 342-carat rough diamond has resulted in a set of 23 diamonds, the Garden of Kalahari. Highest precision could be achieved thanks to LMJ.

Application Areas

Diamonds & JewelryCutting of Large Diamonds

Material

Natural DiamondProcess

Cutting

The Constellation

The 813-carat Constellation Diamond is the most expensive rough diamond in the world. The resulting 313-carat ‘Constellation One’ is the largest D color emerald cut diamond ever.

Application Areas

Diamonds & JewelryCutting of Large Diamonds

Material

Natural DiamondProcess

Cutting

143.45 Carat Diamond

This expensive and valuable diamond has been cut to perfection. Laser MicroJet technology ensures minimal weight loss thanks to parallel cutting.

Application Areas

Diamonds & JewelryCutting of Large Diamonds

Material

Natural DiamondProcess

CuttingCutting for Jewelry Industry

Hole Drilling for Jewellery

To link the diamond with the other jewellery part, a hole-drilling process might be required. With LMJ the drilled holes are fully straight, no V-shape, no chipping at the hole entry and exit.

Application Areas

Diamonds & JewelryCutting for Jewelry Industry

Material

Natural DiamondProcess

Hole-Drilling

Fancy Bruting

The LMJ is advantageously for fancy bruting due the its perfect cut at the outline of the diamond to create the shape profile. Less post-processing is required.

Application Areas

Diamonds & JewelryCutting for Jewelry Industry

Material

Natural DiamondProcess

BrutingCutting of Lab Grown Diamonds

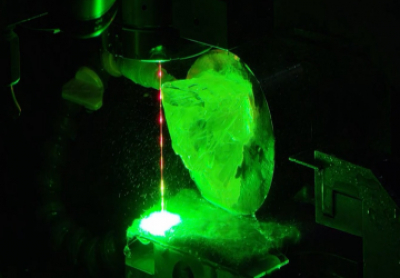

Slicing of a CVD Crystal

The aim is to obtain a maximum number of slices from the CVD crystal. Cutting with a constant parallel kerf and without tapering with LMJ ensures a higher yield.

Application Areas

Diamonds & JewelryCutting of Lab Grown Diamonds

Material

CVD CrystalProcess

Slicing

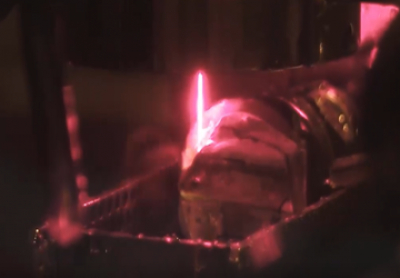

Slicing of a HPHT Diamond

The goal is to get a maximum number of slices out of the HPHT crystal (high pressure, high temperature) and to cut variable thicknesses ranging up to 12 mm.

Application Areas

Diamonds & JewelryCutting of Lab Grown Diamonds

Material

HPHT CrystalProcess

Slicing

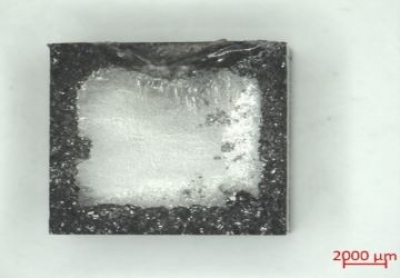

Coring and Slicing of a CVD Crystal

With LMJ there was an improvement in yield, straightness, smoothness, cracks, and throughput in coring and slicing CVD crystals.

Application Areas

Diamonds & JewelryCutting of Lab Grown Diamonds

Material

CVD CrystalProcess

SlicingCoring

Coring for Graphite Removal

The use of LMJ ensures a high quality coring and slicing process of CVD crystals and smooth surfaces as well as low roughness what requires minimal post treatments.

Application Areas

Diamonds & JewelryCutting of Lab Grown Diamonds

Material

CVD CrystalProcess

SlicingCoring

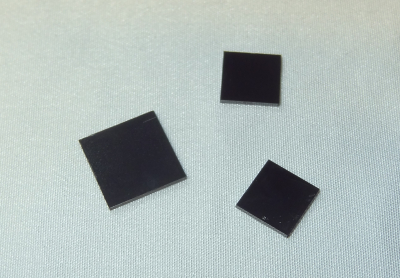

Lab Grown Diamond Material for Industry

The LMJ is used for cutting components with free froms with high accuracy requirements (± 5 μm) from CVD crystals.

Application Areas

Diamonds & JewelryCutting of Lab Grown Diamonds

Material

CVD CrystalProcess

SlicingCoring

3D Form Cuts

CVD Seed Slicing

The challenge was to slice large CVD crystals (chemical vapor deposition) of up to 25 mm from a single direction and along the largest thickness, with a high quality.

Application Areas

Diamonds & JewelryCutting of Lab Grown Diamonds

Material

CVD CrystalProcess

SlicingCoring

Watchmaking

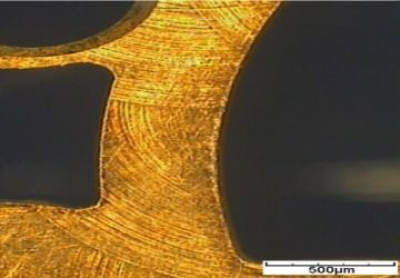

Cutting of Watch Components for Luxury Watches

With very short warm-up and set-up times Synova's Laser MicroJet (LMJ) is a flexible and stable tool to cut watch components for luxury watches, no matter if it's for production or prototyping.

Application Areas

WatchmakingMaterial

GoldProcess

Cutting

Cutting of Oscillating Parts

The LMJ is used to cut oscillating monolithic parts with complex shapes without deformation or heat affected zone but with the capacity to cut very thin bridges.

Application Areas

WatchmakingMaterial

SteelCopper

Process

Cutting

Cutting of Watch Dials and Markers

The LMJ is used to cut large series of up to 2mm thick decorative watch components.

Application Areas

WatchmakingMaterial

GoldSteel

Brass

Process

DrillingCutting

Medical

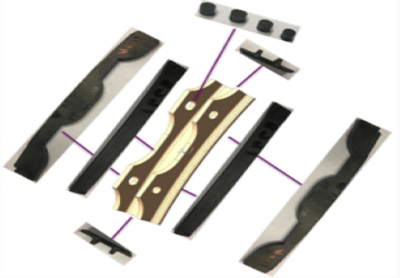

Cutting of Silicon Blades

The silicon blades for the first single-use, safety engineered surgical knife designed for use in cutting corneal tissue were cut with Synova's LMJ.

Application Areas

MedicalMaterial

SiliconProcess

Cutting

Cutting of Nitinol Stents

LMJ was the perfect choice to receive a controlled/homogeneous roughness, narrow tolerances, no HAZ, and no reduction in strength cut cardiovasculaire stents.

Application Areas

MedicalMaterial

NitinolProcess

CuttingSemiconductors and Photovoltaics

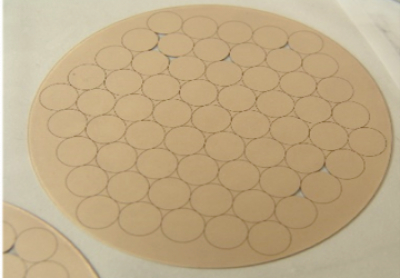

Downsizing of Silicon Wafers

The LMJ is used for gentle, precise, and fast processing for large inline production of power semiconductor devices. Low contamination of the workpiece is crucial.

Application Areas

Semiconductors & PhotovoltaicsMaterial

SiliconProcess

Cutting

Singulation of Silicon Wafers

| The LMJ is used for hexagonal square or circular dies singulation for PressFIT Diodes and achieves a much better edge quality compared to grinding. |

Application Areas

Semiconductors & PhotovoltaicsMaterial

Silicon with gold coatingProcess

Cutting

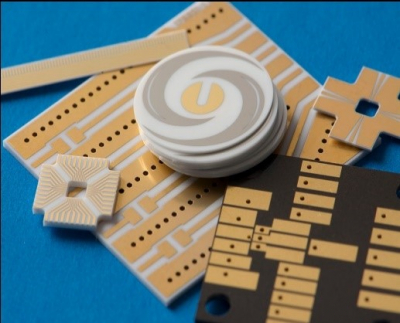

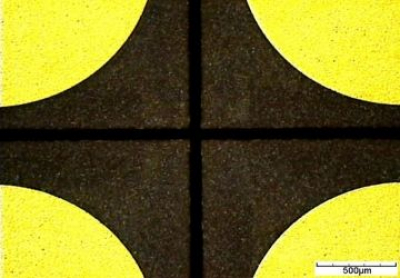

Dicing of Ceramic Circuits

With LMJ, it was possible to establish a repeatabel, high-speed process for singulating substrates without damaging the adjacent circuitry.

Application Areas

Semiconductors & PhotovoltaicsMaterial

CeramicsProcess

Dicing

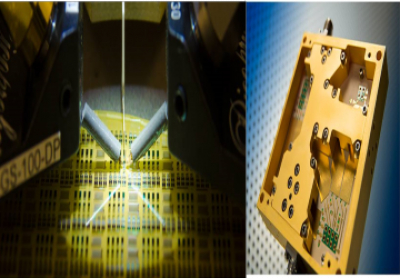

Wafer Dicing

LMJ: wafer dicing, device singulation. Elimination of high operational costs for blades.

Application Areas

Semiconductors & PhotovoltaicsMaterial

Natural DiamondSilicon Carbide

Advanced Materials such as GaN

Process

DicingSingulation

Cutting of IGTB Power Chips

LMJ is the perfect choice to cut silicon carbide which is a challenging material to cut because of its hardness and brittleness. In this case it is used for IGTB Power Chips.

Application Areas

Semiconductors & PhotovoltaicsMaterial

Silicon CarbideProcess

Edge GrindingEdge Trimming

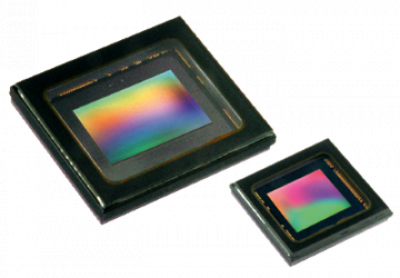

Edge Trimming of CMOS Image Sensors

LMJ is used to trim edges of CMOS image sensors and proves superiority over EDM by significantly higher quality.

Application Areas

Semiconductors & PhotovoltaicsMaterial

SiliconProcess

Edge TrimmingDownsizing

Complementary Metal Oxide

|

Silicon frames are very brittle and request a gentle processing technology without any micro cracks and chipping. LMJ reaches high accuracy, straight walls, low roughness and is highly flexible. |

Application Areas

Semiconductors & PhotovoltaicsMaterial

SiliconProcess

Cutting

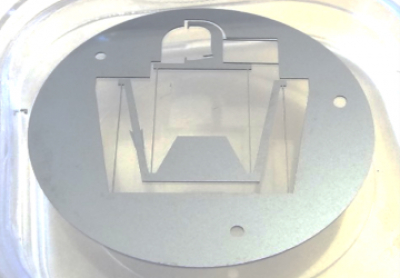

Taiko Ring Removal

Thin wafers are challenging to manipulate and to process due to the high flexibility and fragility. With LMJ the perfect TAIKO ring removal becomes possible.

Application Areas

Semiconductors & PhotovoltaicsMaterial

SiliconProcess

Cutting

Cutting of Platinum-Iridium

LMJ was chosen to dice sensitive platinum-iridium detectors in the form of microchips, it has several advantages over blade sawing.

Application Areas

Semiconductors & PhotovoltaicsMaterial

Platinum-IridiumProcess

DicingSingle Die Cutting

Chamfer Cutting

LMJ is used to downsize 450mm silicon semiconductor wafers to 300mm and 200mm wafers, without any impact on the material.

Application Areas

Semiconductors & PhotovoltaicsMaterial

SiliconProcess

Downsizing

Cutting of LED Chips

LED chips and packages are made of materials that are frequently difficult to cut mechanically. With LMJ one has high flexibility regarding materials and shapes.

Application Areas

Semiconductors & PhotovoltaicsMaterial

Indium Gallium NitrideProcess

Cutting

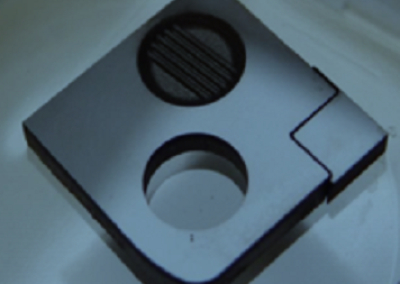

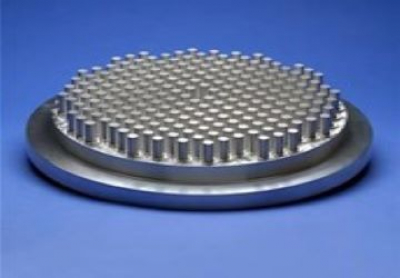

Semiconductor Reactor Sub-Assemblies

LMJ is used for micro-machining semiconductor reactor sub-assembly parts with tight tolerances on thick, hard materials in contact with reactive gas.

Application Areas

Semiconductors & PhotovoltaicsMaterial

CeramicsSilicon

Silicon Carbide

Advanced Composites

Process

DrillingOther MicroMachining Applications

High-Tech Parts

Laser MicroJet (LMJ) is used for micro-machining of high-tech components for the watch, medtech, space and defense industry. It is the perfect tool for flexible, stable and heat damage-free processes.

Application Areas

Other Micro-Machining ApplicationsMaterial

VariousProcess

Micro-Machining

Shaver Caps

LMJ for prototyping, cutting, drilling of demanding shaver caps. Requirements met: damage-free, vertical, and precise processing.

Application Areas

Other Micro-Machining ApplicationsMaterial

Stainless SteelProcess

DrillingCutting

Prototyping

CuBe

| LMJ used for prototyping on CuBe, damage-free cutting and drilling. LMJ has high flexibility for lower production volumes, no deburring needed. |

Application Areas

Other Micro-Machining ApplicationsMaterial

CuBeProcess

DrillingCutting

Prototyping

High-Tech Components

LMJ, heat damage-free processing high-tech components; medtech, micro-machining.

Application Areas

Other Micro-Machining ApplicationsMaterial

VariousProcess

DrillingCutting

Prototyping

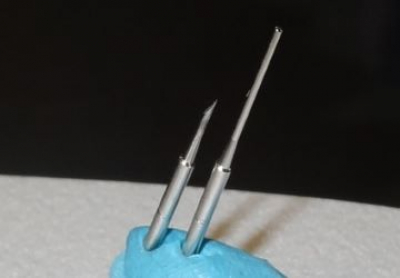

Cutting of Platinum Electrodes

The main challenge to cut platinum electrodes is to reach to the electrode which is welded more than 20mm deep in a cylinder. Processing with LMJ is much faster than with EDM.

Application Areas

Other Micro-Machining ApplicationsMaterial

PlatinumProcess

Cutting

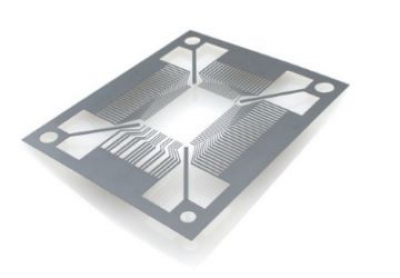

Shadow Mask Patterning

LMJ is used to cut and drill thin nickel masks, so called shadow mask patterning. Nickel foils are challenging to cut/ablate due to the large size and low thickness.

Application Areas

Other Micro-Machining ApplicationsMaterial

Nickel FoilsProcess

DrillingCutting